PLASMA iQC 70 T

To be compulsorily coupled to CP 71C MAR [Art. 1629] or DAR [1630] torchINVERTER THREE-PHASE POWER SOURCE FOR PLASMA CUTTING. ‘ON AIR’ IGNITION

![]() 400/440 V 50/60 Hz ± 10%

400/440 V 50/60 Hz ± 10%![]() Thickness on mild steel:

Thickness on mild steel:

25 mm: reccomended

30 mm: maximum

35 mm: severance

15 mm: pierce capacity

Benefits

Simple and intuitive color LCD display

To be coupled with the new torch with Esafast® adaptor

Additional functions: Fast Restart, Spot, Mark, Gouge

“Plasma Synergy” kit with automatic pressure regulator

Our power sources have got International Certifications and Approvals ![]()

Download

Parts and support

Count on our fast support, maintenance and parts supply services to ensure work continuity.

Extend your warranty!

Just bought a new Cebora welding power source? Register your product within 15 days to extend your warranty from 12 to 24 months.

Choose Plasma cutting Cebora

PLASMA iQC 70 T

The new iQC plasma cutting line consists of three-phase power source with digital inverter technology featuring "ON AIR" ignition and torch recognition system via hardware key.

- Control panel with 4.3" high-resolution color LCD display

- Synergistic setting of cutting parameters

- Display of the number and duration of ignitions and total cutting time

- Automatic recognition of torch model, type, and length via hardware key.

- Color graphical display of the set of consumables in use

- "Fast Restart" (designed for continuous cutting of metal meshes without extinguishing the pilot arc) and "Spot" functions

- Operating modes:

- Gas cutting: Air and nitrogen N2

- Gas marking: Air (up to 5 A)

- Gouging (Maximum material removal quantity: 5,8 kg/h) - New CEBORA CP71C torch (Art. 1629 - 1630) to be compulsorily coupled with the power source with lengths of 6 and 15 meters (MAR and DAR) with ESAFast® adaptor. ESAFast® is the new 11-pin centralized adaptor with a pleasant and compact hexagonal design, from which it draws inspiration.

- Possibility to update the software via USB stick.

- Power source suitable for power motor-generators with a capacity equal to 1.5 times the generator power, even if not equipped with AVR (Automatic Voltage Regulator).

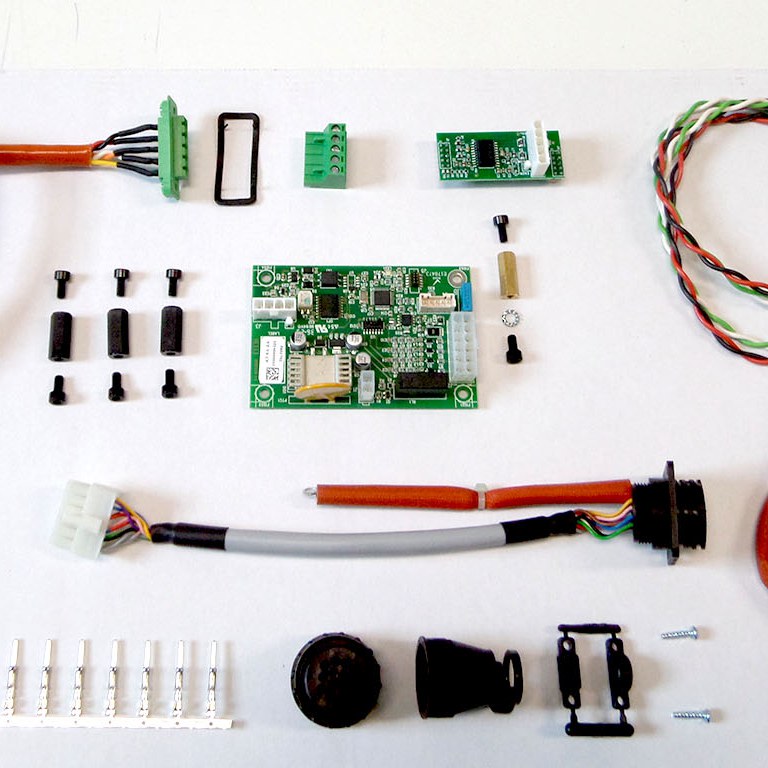

- "Plasma synergy" kit with automatic pressure regulator (Art. 503)

Ideal solution for a fully automated plasma cutting system, suitable for every material and working condition, which allows:

- Real-time gas regulation and control;

- Automatic management of cutting, marking, gouging, and gouging processes;

- Automatic setting of cutting parameters based solely on material and thickness.

| Art. | 601 | Technical Specifications |  |

|

|---|---|---|---|---|

|

400/440V |

Alimentazione trifase |

|||

|

16 A |

|

Fusibile ritardato |

||

|

9,7 kVA 70% |

Potenza assorbita |

|||

|

10 ÷ 70 A |

|

Campo di regolazione della corrente |

|

|

70 A 70% |

|

Fattore di servizio (10 min. 40° C) |

||

|

ELECTRONIC |

Regolazione continua |

|||

|

25 - 30 - (35) mm |

Spessori su acciaio: Raccomandato - Max - (Separazione) - |

||

|

230 l/min @ 5.5 bar |

Consumo aria |

||

|

IP23S |

Grado di protezione |

|||

|

24,5 kg |

Peso |

|||

|

232x562x477 mm |

Dimensioni (LxPxH) |

|||

- Chemical industry

- Heavy metal fabrication

- Building and road construction industry

- Handcrafting

- Food Industry

- Industrial & Energy plant

- Construction of agricultural,railway and heavy vehicles

- Off-shore industry

- Miniere