Sectors

SYNSTAR 330 TS

MULTIPROCESS INVERTER THREE-PHASE COMPACT POWER SOURCE FOR MIG/MAG, DC TIG and MMA WELDING WITH SEPARATE WIRE FEED UNIT

![]() 400 V 50/60 Hz +15%/ -20%

400 V 50/60 Hz +15%/ -20%

Benefits

User-friendly LCD touchscreen Display

Pulse and Double Pulse functions

4-roller wire feed unit and over 70 welding programs

Software updating in few seconds

Our power sources have got International Certifications and Approvals

![]()

Download

Parts and support

Count on our fast support, maintenance and parts supply services to ensure work continuity.

Extend your warranty!

Just bought a new Cebora welding power source? Register your product within 15 days to extend your warranty from 12 to 24 months.

Choose MIG/MAG Cebora

SYNSTAR 330 TS

The new SYNSTAR 330 TS is a multiprocess synergic inverter three-phase (400 V 50/60 Hz +15% / -20%) power source for MIG/MAG, DC TIG (WITH 'Cebora lift' ignition) and MMA welding, with 4-roller Cebora wire feed unit

- Aluminium 4-rollerwire feed unit (Ø 30 mm)

- Equipped with power source transportation trolley, ground lead ( 3 m - 50 mm2) and clamp

- Pre-arranged for cooling unit

- More than 70 welding programs for wires Ø 0,8/0,9/1,0/1,2mm., and also for pulsed synergic programs optimized for welding of thin thicknesses

- Supplied with double level of current (MIG Short process), Pulse and double Pulse

- Pulse TIG upgrade [Art. 234]

- The power source has many adjustable functions which can be accessed from 5 ” colour Display Touchscreen, including:

- Arc Length, 2/4 strokes, Spot Time, Pause Time, Inductance, Burn Back, Soft Start, post-pre gas, etc.

- SHORT or PULSE function

-Three importants specific functions dedicated to an optimal aluminum welding (3 levels, Automatic Hot Start, Automatic Crater Filler) - Firmware update through USB port

- The power source is pre-arranged for the wireless connectivity to the welding mask with auto-darkening filter

- Second gas connection and additional dedicated solenoid valve when using the power source in TIG mode

[Art. 388.55] Strong version on request with 50/60 Hz three-phase autotransformer (200) - 220 - 440 - 480 V

It is available, on request:

- [Art. 2060] extension lead between power source and trolley

-

CEBORA PUSH-PULL (UP/DOWN) torch

[Art. 2003] -

'CEBORA 380A’ torch

[Art. 1239] -

'CEBORA 380A’ torch - Water-cooled

[Art. 1241] -

BINZEL 'ABITIG 450 W’ TIG torch

[Art. 1256] -

'CEBORA 500A’ (UP/DOWN) torch - Water-cooled

[Art. 1245] -

GRV14 torch cooling unit

[Art. 1681] -

Flowmeter with 2 pressure gauges

[Art. 1450] -

4.3 m sheath assembly for aluminium wire

[Art. 1930] -

Aluminium kit

[Art. 1933] -

Connection between power source and TIG torch

[Art. 2068] -

Digital-analogue adapter kit for UP/DOWN torch connector

[Art. 2053] -

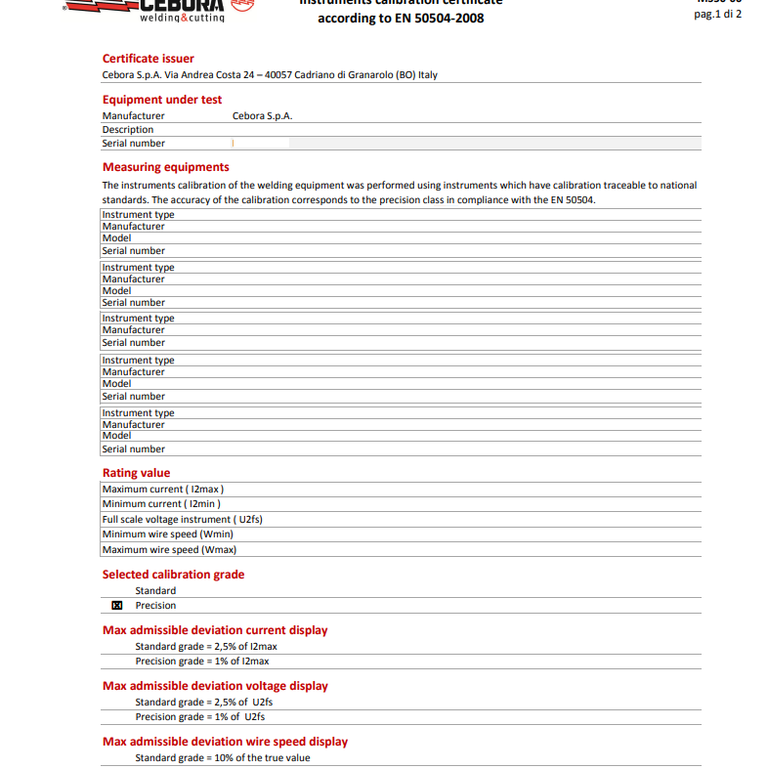

Calibration certificate

[Art. 803]

| Art. | 388 | Techinal Specifications | ||

|---|---|---|---|---|

|

MIG - TIG |

MMA |

|

||

|

400 V 50/60 Hz |

|

Alimentazione trifase |

|

|

16 A |

|

Fusibile ritardato |

||

|

12,4 kVA 40% |

11,6 kVA 40% |

Potenza assorbita |

||

|

10 ÷ 330 A |

|

Corrente min.-max. ottenibile in saldatura |

||

|

330 A 40% |

300 A 40% |

Fattore di servizio (10 min. 40° C) |

||

|

Electronic |

|

Regolazione continua |

||

|

0,8/0,9/1,0/1,2 Fe |

|

Curve sinergiche in dotazione standard |

||

|

Ø 300 mm/15 kg |

|

Bobina filo trainabile max. |

||

|

IP23S |

|

Grado di protezione |

||

|

82 kg |

|

Peso |

||

|

510x1022x1330 mm |

|

Dimensioni (LxPxH) |

||

- Chemical industry

- Medium-heavy metal fabrication

- Construction

- Building and road construction industry

- Handcrafting

- Food industry

- Industrial & Energy plant

- Construction of agricultural, railway and heavy vehicles

- Routine maintenance

- Construction of tanks

- Off-shore industry

- Mines