Sectors

KINGSTAR 400 TS

MULTIPROCESS INVERTER THREE-PHASE POWER SOURCE FOR MIG/MAG, DC TIG AND MMA WELDING

![]() 400 V +15%/ -20% 50/60 Hz

400 V +15%/ -20% 50/60 Hz

Benefits

Suitable for SWPS special package

User-friendly LCD touchscreen Display

Pre-arranged for Pulse, Double Pulse, SRS and 3DPulse

4-roller wire feed unit and over 100 synergic curves

Remote control e data backup

Compliant with Industry 4.0

Our power sources have got International Certifications and Approvals

![]()

Download

Parts and support

Count on our fast support, maintenance and parts supply services to ensure work continuity.

Extend your warranty!

Just bought a new Cebora welding power source? Register your product within 15 days to extend your warranty from 12 to 24 months.

Choose MIG/MAG Cebora

KINGSTAR 400 TS

KINGSTAR 400 TS is a multiprocess inverter three-phase (400 V 50/60 Hz +15% / -20%) power source for MIG/MAG, DC TIG (with 'Cebora lift' ignition) and MMA welding. Equipped with devoted connection for a standard TIG torch and solenoid valve welding

- Cebora aluminium 4-roller-wire feed unit (Ø 37 mm)

- Equipped with transportation trolley, ground lead and clamp ( 3,5 m - 70 mm2 )

- Pre-arranged for cooling unit

- 7 "LCD touchscreen control panel

- MIG SHORT HD (High Deposit) and MIG ROOT (First Pass) functions

- Upgrade MIG Pulse and HD Pulse [Art. 231]

- Upgrade MIG double current level function [Art. 233]

- Upgrade MIG Double Pulse [Art. 231 + 233]

- Upgrade full TIG [Art. 804]

- Pre-arranged for MIG SRS standard welding process (Spatter Reduction System) in order to completely achieve spatters free welds and with reduced heat input [Art. 443]

- Upgrade MIG 3DPulse [Art. 814]

- Advanced users: software package for the advanced users management [Art. 809]

- Quality control: software package for the quality control [Art. 273]

- Production mode: software package for production management [Art. 817]

- SWPS Package according to ISO 151612 which meets the qualification requirements of the procedures according to EN 1090-1; [Art. 808]

- System calibration procedure which allows complete adjustment of all welding parameters and process variables (from the features of the welding torch, to the extension lead used between the transporting trolley and the power source);

- Easily removable cooling grille

- JOB function for store up to 99 welding programs

- Power source / wire feed connection with bayonet connector compliant with MIL-C-SS 116 standards that eliminates the problem of inserting and fixing the signal cable;

- USB port for software update

- Compliant with Industry 4.0 (Integrated web server with LAN connection - 2 USB port that provides useful functions for remote service, diagnostics, information system, backup and data recovery)

- Remote control mode from personal computer, tablet or smartphone

- Equipped with digital ammeter / voltmeter with 1% accuracy and thermal protection devices

- MIG/MAG torch with "Euro" adapter + TIG torch adapter

- Second gas connection and additional dedicated solenoid valve when using the power source in TIG mode

[Art. 372.55] Strong version on request with 50/60 Hz, (200) – 220 – 440 – 480 V, three-phase autotransformer

| Art. | 372 | Technical Specifications | ||

|---|---|---|---|---|

|

MIG - TIG |

MMA |

|

||

|

400 V 50/60 Hz |

|

Alimentazione trifase |

|

|

20 A |

|

Fusibile ritardato |

||

|

18,8 kVA 40% |

17,7 kVA 40% |

Potenza assorbita |

||

|

10 ÷ 400 A |

|

Corrente min.-max. ottenibile in saldatura |

||

|

400 A 40% |

380 A 40% |

Fattore di servizio (10 min. 40° C) |

||

|

Electronic |

|

Regolazione continua |

||

|

0,8/0,9/1,0/1,2/1,6 Fe |

|

Filo utilizzabile |

||

|

Ø 300 mm/15 kg |

|

Bobina filo trainabile max. |

||

|

Ø 1,5 ÷ 6,0 |

Elettrodi utilizzabili |

||

|

IP23S |

|

Grado di protezione |

||

|

120 kg |

|

Peso |

||

|

588x1120x1380 mm |

|

Dimensioni (LxPxH) |

||

-

'CEBORA 380A’ torch

[Art. 1239] -

'CEBORA 380A’ torch - Water-cooled

[Art. 1241] -

'CEBORA 500A’ (UP/DOWN) torch - Water-cooled

[Art. 1245] -

BINZEL 'ABITIG 450 W’ TIG torch

[Art. 1256] -

BINZEL 'ABITIG 450 W' UP/DOWN TIG torch

[Art. 1258] -

24 Vdc - power supply kit for external Wi-Fi router

[Art. 451] -

Flowmeter with 2 pressure gauges

[Art. 1450] -

GRV12 torch cooling unit

[Art. 1683] -

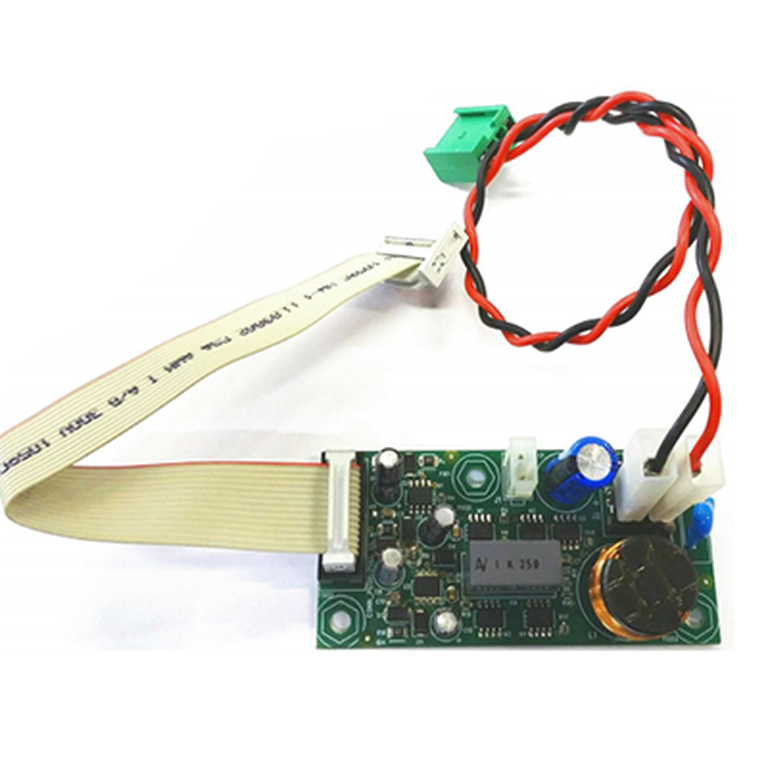

Connection between power source and wire feeder unit

[Art. 2061] -

Kit gas flow regulator

[Art. 436.01] -

Wire feeder DIGIBOX panel remote control kit

[Art. 437] -

Connection between power source and control panel

[Art. 2065] -

4.3 m sheath assembly for aluminium wire

[Art. 1930] -

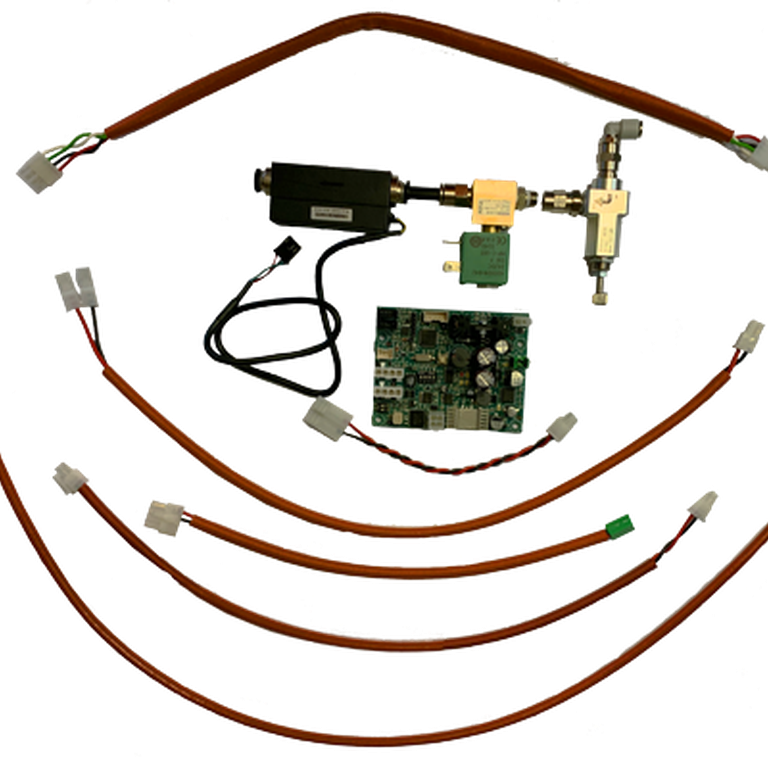

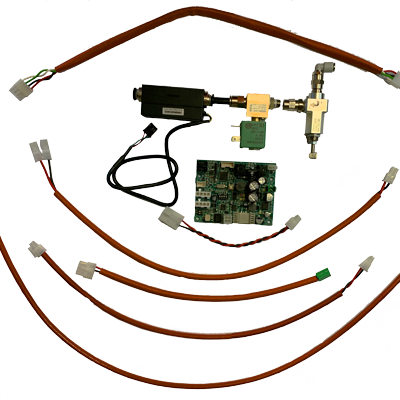

Aluminium kit

[Art. 1933] -

Kit driver PUSH-PULL

[Art. 447] -

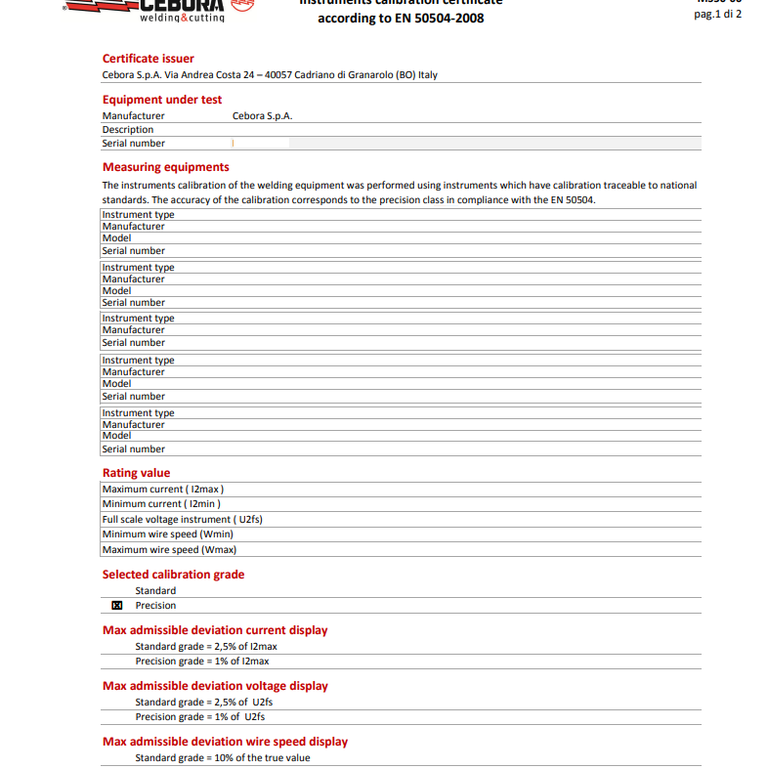

Calibration certificate

[Art. 803] -

SWPS

[Art. 808] -

Double wire feeder-unit kit

[Art. 458]

- Chemical industry

- Heavy metal fabrication

- Shipbuilding

- Building and road construction industry

- Handcrafting

- Food industry

- Industrial & Energy plant

- Construction of agricultural, railway and heavy vehicles

- Construction of tanks

- Mines