Sectors

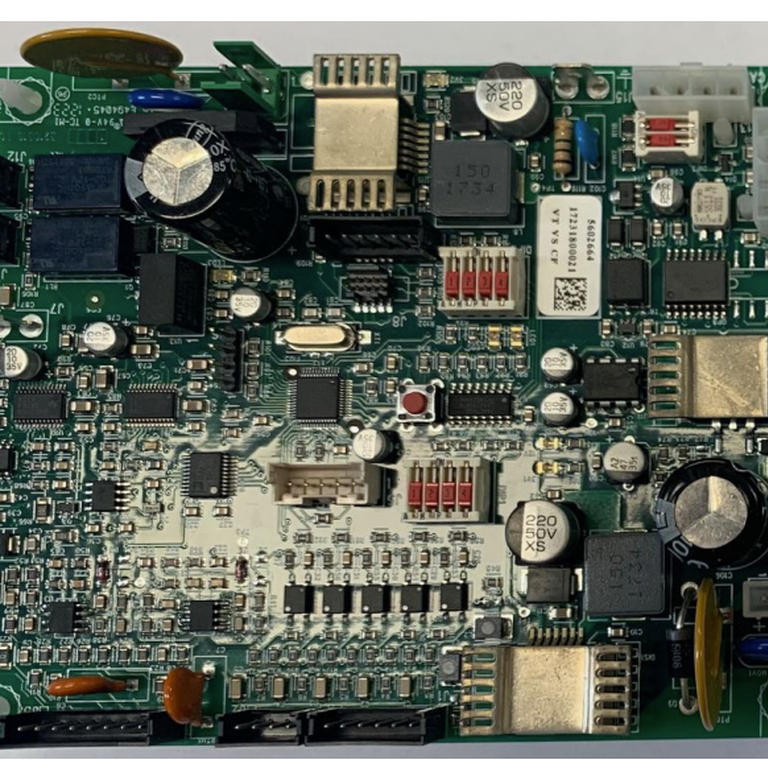

WIN TIG DC 320 T

INVERTER THREE PHASE COMPACT POWER SOURCE FOR DC TIG AND MMA WELDING. HIGH FREQUENCY IGNITION

![]() 400 V +15%/-20% 50/60 Hz

400 V +15%/-20% 50/60 Hz

Benefits

5" Display LCD touch screen display

Evo Lift Ignition for a even more precise arc ignition

TIG functions available

Pulse TIG DC as standard

Our power sources have got International Certifications and Approvals

![]()

Download

Parts and support

Count on our fast support, maintenance and parts supply services to ensure work continuity.

Extend your warranty!

Just bought a new Cebora welding power source? Register your product within 15 days to extend your warranty from 12 to 24 months.

Choose TIG Cebora

WIN TIG DC 320 T

WIN TIG DC 320 T is a three-phase inverter technology generator for TIG and MMA/-SMAW welding designed for maintenance purposes.

- User-friendly 5" LCD touch screen display

- New cooling unit and trolley for transportation

- EVO LIFT function allows to place the electrode in the exact position avoiding the piece oxidation and the heat control

- EVO START function in order to optimize edge junction

- APC TIG (Active Power Control) welding process which guarantees a deeper penetration, a more stable arch, avoids the electrodes to get stuck to the piece, allows to adapt the arc to the welding conditions only with the torch movement

- Intermittence pause time welding function which makes welding clearer with a time regulation in a second cents range

- DC TIG process with a minimum current of 3 A useful to carryover operations on metal mould edges.

- DC PULSE process as standard

- eXtra Pulse (XP) function: avery high frequence pulse that works on small thicknesses where the transferred heat must be minimal

- Fast spot welding with minimal heat input due to the specific function that allows accurate adjustment (in 10 ms steps) of welding time and intermittent time suitable for DC spot welding work on thin sheets.

- VRD (Voltage Reduction Device) function: in MMA mode, enhances safety in dangerous environments.

- JOB function which makes it possible to save up to 99 welding programs

- USB port

- Prearranged for integration into simple automation via optional analog interface kit (Art. 456)

- Remote control panel kit. To be compulsorily coupled to art. 2065 (Art. 457)

| Art. | 560 | Techinal Specifications | ||

|---|---|---|---|---|

| TIG | MMA | |||

|

400 V |

Alimentazione trifase |

|||

|

16 A |

Fusibile ritardato |

|||

|

9 kVA 30% |

9,5 kVA 40% |

Potenza assorbita |

||

|

3 ÷ 320 A |

10 ÷ 260 A |

Campo di regolazione della corrente |

||

|

320 A 30%

|

260 A 40% 230 A 60% 190 A 100% |

Fattore di servizio (10 min. 40° C) |

||

|

IP23S |

Grado di protezione |

|||

|

24 kg |

Peso |

|||

|

232 x 530 x 467 mm |

Dimensioni (LxPxH) |

|||

-

BINZEL 'ABITIG 200’ TIG torch

[Art. 1260] -

BINZEL 'ABITIG 200' UP/DOWN TIG torch

[Art. 1262] -

BINZEL 'ABITIG 450 W’ TIG torch

[Art. 1256] -

BINZEL 'ABITIG 450 W' UP/DOWN TIG torch

[Art. 1258] -

GVR20 cooling unit

[Art. 1685] -

Analog interface kit

[Art. 456] -

Connection between power source and control panel

[Art. 2065] -

Power source transport trolley

[Art. 1676] -

Remote control for regulating welding current

[Art. 187] -

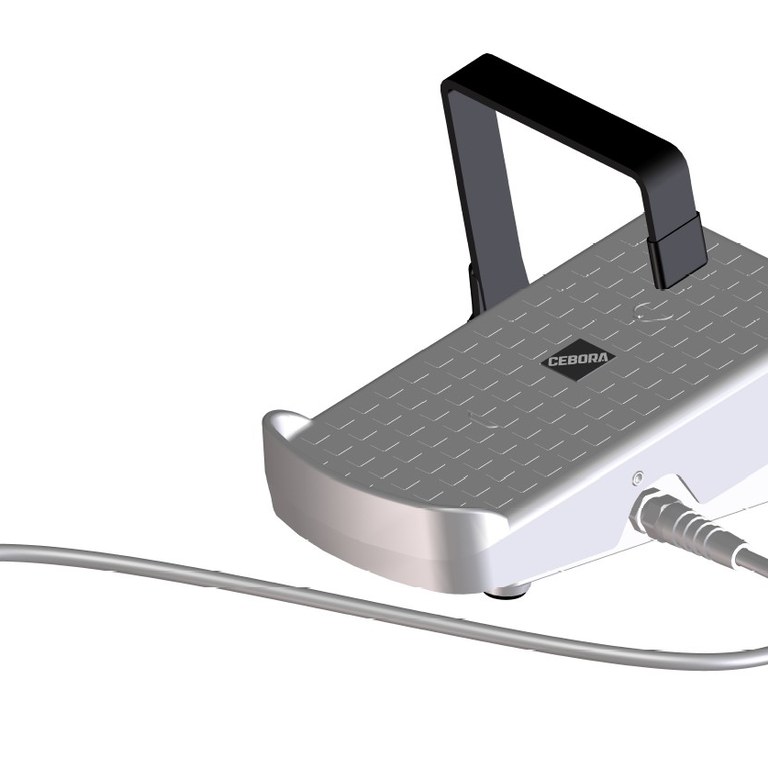

Wireless pedal control for welding current adjustment

[Art. 189] -

Wireless pedal control for welding current adjustment

[Art. 127] -

5 m extension cable for remote control

[Art. 1192] -

Connection linking torch and pedal control

[Art. 1180] -

Work return lead (3,5 m - 50 mm²)

[Art. 2073] -

Flowmeter with 2 pressure gauges

[Art. 1450] -

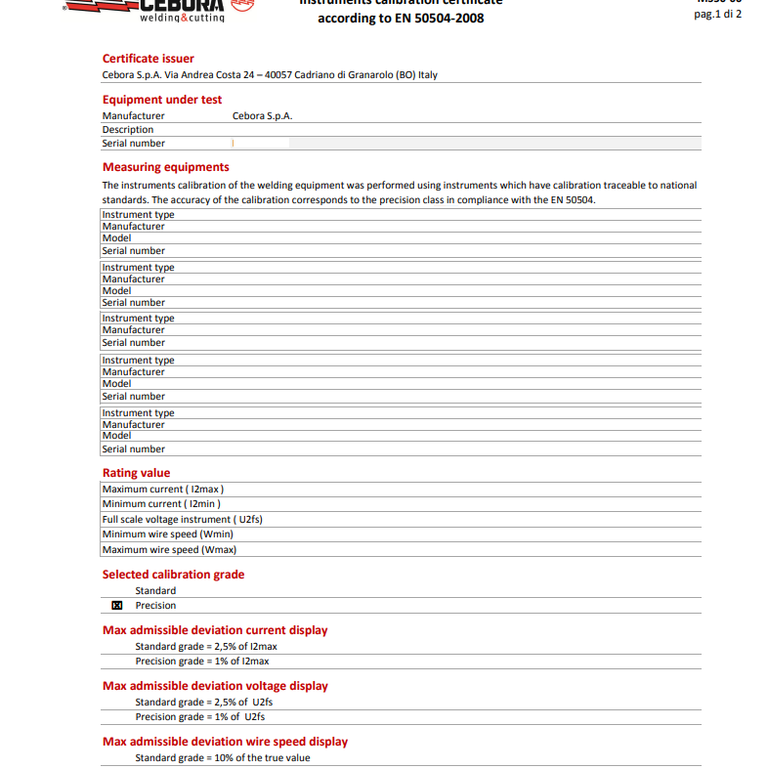

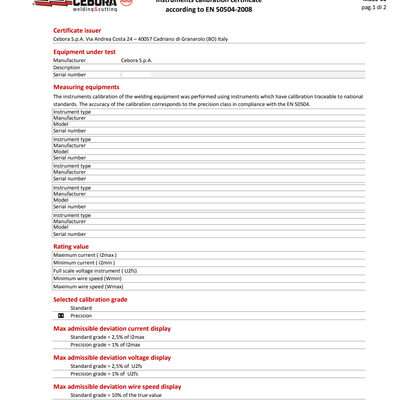

Calibration certificate

[Art. 803]

- Light metal fabrication

- Handcrafting

- Food industry

- Body shop

- Industrial & Energy plant

- Routine maintenance

- Agricultural industry

- Construction of tanks

- Off-shore industry