Sectors

WIN TIG DC 350 T ROBOT

INVERTER THREE-PHASE COMPACT POWER SOURCE FOR DC TIG WELDING. HIGH FREQUENCY IGNITION

![]() 400 V ±15% 50/60 Hz

400 V ±15% 50/60 Hz

Benefits

User-friendly LCD touchscreen Display

Equipped with XP and Pulse+XP functions

Compliant with Industry 4.0

Webapp for remote control and data backup via tablet

Our power sources have got International Certifications and Approvals

![]()

Download

Parts and support

Count on our fast support, maintenance and parts supply services to ensure work continuity.

Extend your warranty!

Just bought a new Cebora welding power source? Register your product within 15 days to extend your warranty from 12 to 24 months.

Choose TIG Cebora

WIN TIG DC 350 T ROBOT

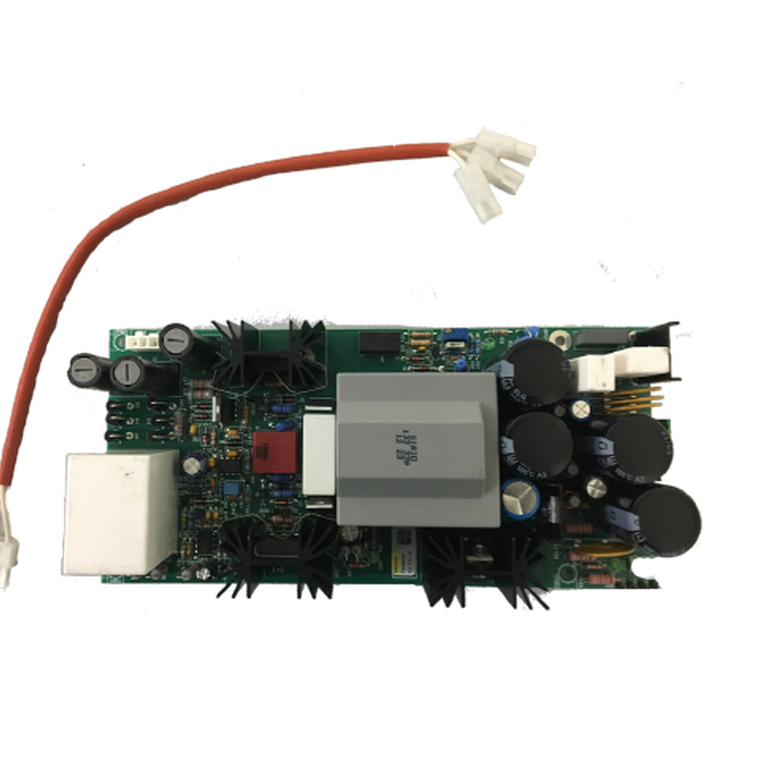

Inverter three-phase (400 V 50/60 Hz ±15%) pulse and direct DC TIG welding power source. High Frequency Ignition

- 7” LCD touchscreen multilanguage Display

- Optional cooling unit

- Equipped with robot digital CANopen interface; Further digital or analogic interfaces on request

- WF5 COLD WIRE Unit for the cold wire process, also pulsed synchronously with welding current

- EVO LIFT function allows to place the electrode in the exact position avoiding the piece oxidation and the heat control

- EVO START function in order to optimize edge junction

- APC TIG (Active Power Control) welding process which guarantees a deeper penetration, a more stable arch, avoids the electrodes to get stuck to the piece, allows to adapt the arc to the welding conditions only with the torch movement

- Pulse function to be adjusted up to 2,5 kHz

- eXtra Pulse (XP) function: a very high frequence pulse that works on small thicknesses where the transferred heat must be minimal

- Possibility to match a low pulse frequence to the XP process in order to improve the penetration and the welding speed on small-medium thicknesses.

- JOB function which makes it possible to save up to 99 welding programs

- Advanced users: software package for the advanced users management [Art. 809]

- Quality control: software package for the quality control [Art. 273]

- Production mode: software package for production management [Art. 817]

- Minimum DC current equal to 3 A

- Compliant with Industry 4.0 the new hardware structure implements a web server (through the Ethernet LAN port or, with an external kit, via Wi-Fi) that allows the operator to carry out all those activities that require the collection and processing of data, welding parameters configuration, diagnostics and remote assistance

- Remote control mode from personal computer, tablet or smartphone

- 2 USB ports for download and software update

- Equipped with digital ammeter/voltmeter with 1% accuracy and thermal protection devices

- Easily removable cooling grille

[Art. 380.85] Strong version on request with 50/60 Hz, (200) - 220 - 440 - 480V, three-phase autotransformer

| Art. | 380.80 | Technical Specifications | ||

|---|---|---|---|---|

|

TIG |

PLASMA WELDING | |||

|

400 V 50/60 Hz |

400 V 50/60 Hz ± 15% |

Alimentazione trifase |

|

|

16 A |

16 A |

Fusibile ritardato |

||

|

10 kVA 40% |

10,4 kVA 40% |

Potenza assorbita |

||

|

3 ÷ 340 A |

3 ÷ 250 A |

Campo di regolazione della corrente |

||

|

340 A 40% |

250 A 40% 230 A 60% 210 A 100% |

Fattore di servizio (10 min. 40° C) |

||

|

IP23S |

Grado di protezione |

|||

|

53 kg |

Peso |

|||

|

410 x 610 x 810 mm |

Dimensioni (LxPxH) |

|||

-

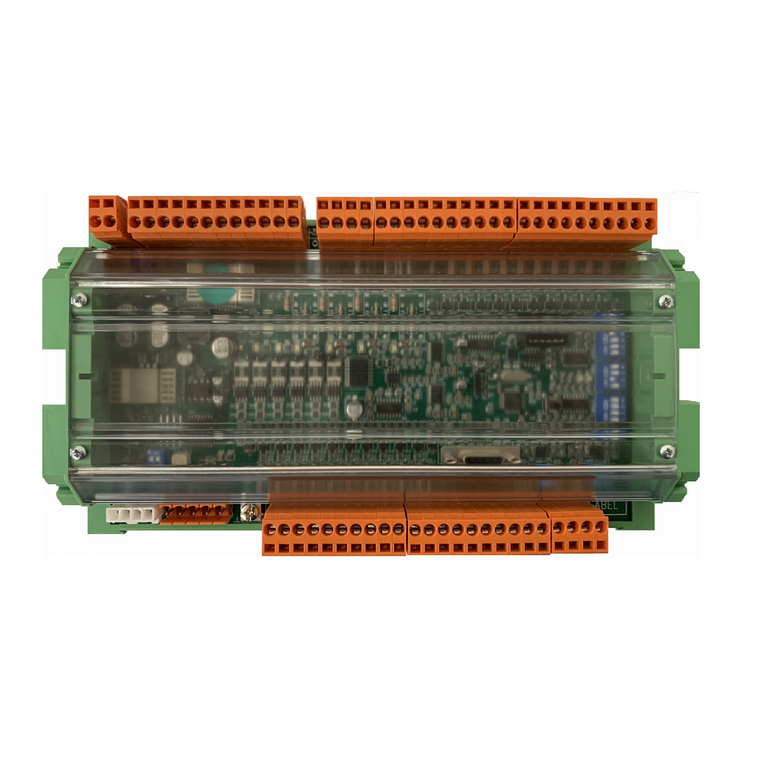

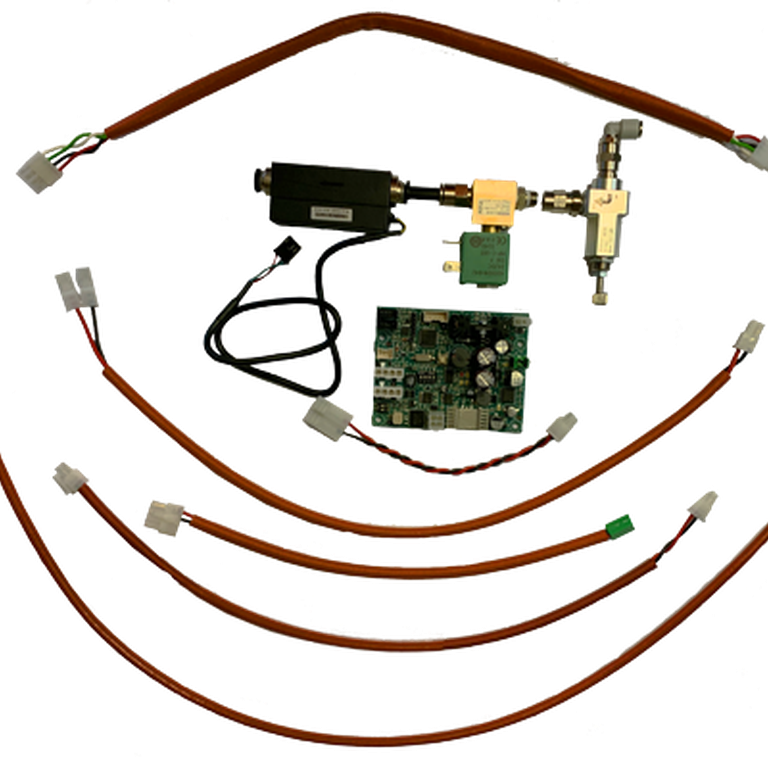

Kit robot analog interface RAI

[Art. 448] -

Kit robot interface RDI Digital

[Art. 428] -

Connection between power source and robot interface

[Art. 2063] -

Robot wire feeder WF5 with 4-roller wire feeder

[Art. 1649] -

Connection between power source and control panel

[Art. 2065] -

Remote control panel

[Art. 438] -

GRV12 torch cooling unit

[Art. 1683] -

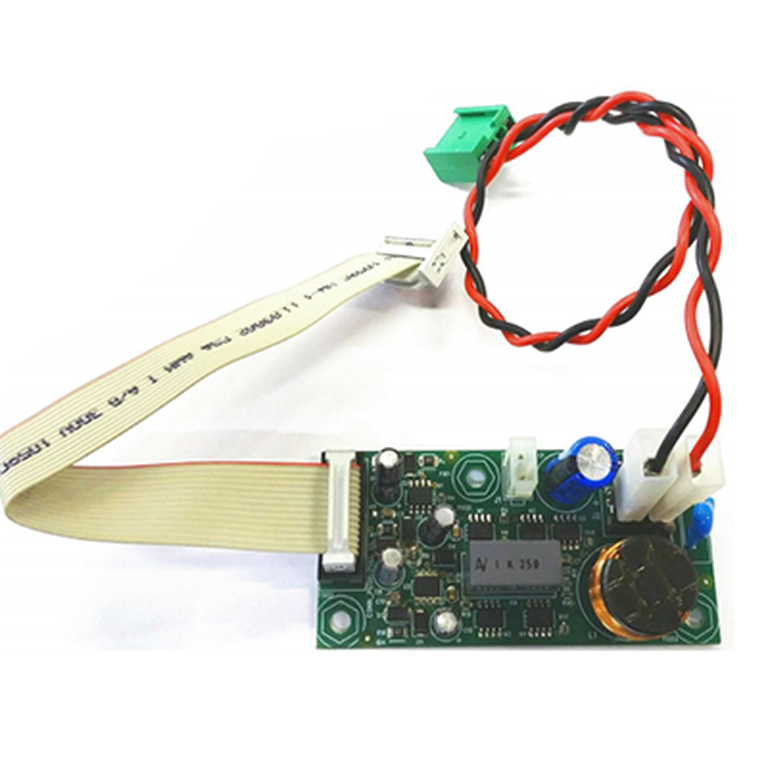

PW30 Digital Console

[Art. 465.01] -

Connection between power source and wire feeder unit

[Art. 2062] -

Welding power source-PW30

[Art. 2067] -

WF5 COLD WIRE Robot wire feeder power supply kit

[Art. 435] -

Kit gas flow regulator

[Art. 436.01] -

Kit driver PUSH-PULL

[Art. 447] -

Kit Emergency + Varc

[Art. 449] -

External HF unit

[Art. 450] -

Robot Analyzer for USB

[Art. 125.01] -

Quick fitting for welding bulk drum system

[Art. 173] -

Spool holder with bracket for robot

[Art. 121] -

Welding wire liner

[Art. 1935] -

CAN2 connection for integrated robot interface CANopen

[Art. 2054] -

24 Vdc - power supply kit for external Wi-Fi router

[Art. 451] -

Calibration certificate

[Art. 803]

- Chemical industry

- Heavy metal fabrication

- Handcrafting

- Food Industry

- Industrial & Energy plant

- Construction of agricultural, railway and heavy vehicles

- Tubistica

- Construction of tanks

- Off-shore industry