Sectors

WIN TIG AC-DC 450 T

INVERTER THREE-PHASE COMPACT POWER SOURCE FOR MMA AND TIG AC-DC WELDING. HIGH FREQUENCY IGNITION

![]() 400 V 50/60 Hz ±15 %

400 V 50/60 Hz ±15 %

Benefits

User-friendly LCD touchscreen Display

Equipped with XP, APC and DC TIG functions

TIG AC, MIX AC+DC and Synergic Waveform functions

Remote control and data backup

Compliant with ad Industry 4.0

AC Frequency is now adjustable from 50 to 200 Hz

Our power sources have got International Certifications and Approvals

![]()

Download

Parts and support

Count on our fast support, maintenance and parts supply services to ensure work continuity.

Extend your warranty!

Just bought a new Cebora welding power source? Register your product within 15 days to extend your warranty from 12 to 24 months.

Choose TIG Cebora

WIN TIG AC-DC 450 T

Inverter three-phase ( 400 V 50/60 Hz ± 15%) power source for pulse TIG and MMA welding. High Frequency Ignition

- 7” LCD touchscreen Display

- Equipped with transportation trolley and cooling unit

- EVO LIFT function allowsto place the electrode in the exact position avoiding the piece oxidation and the heat control

- EVO START function in order to optimize edge junction

- APC TIG (Active Power Control) welding process which guarantees a deeper penetration, a more stable arch, avoids the electrodes to get stuck to the piece, allows to adapt the arc to the welding conditions only with the torch movement

- intermittence Pause Time Welding function which makes welding clearer with a time regulation in a second cents range

- Pulse function to be adjusted up to 2,5 kHz

- eXtra Pulse (XP) function: avery high frequence pulse that works on small thicknesses where the transferred heat must be minimal

- Possibility to match a low pulse frequence to the XP process in order to improve the penetration and the welding speed on small-medium thicknesses.

- JOB function which makes it possible to save up to 99 welding programs

- Minimum DC current equal to 3 A

- Advanced users: software package for the advanced users management [Art. 809]

- Quality control: software package for the quality control [Art. 273]

- Production mode: software package for production management [Art. 817]

- In AC TIG mode, it is possible to independently adjust the width and duration of the penetration and cleaning of half-waves

- AC+DC TIG process for aluminium welding and its alloys

- AC frequency from 50 to 200 Hz

- In AC mode, possibility of selecting several combinations of the three waveforms (square, triangular, sine-wave)

- AC MMA welding process suitable for welding electrodes on magnetized sheet metal, prevents the "magnetic blow" in the welding of iron boxes and it is usually employed in maintenance work

- VRD function: reduces the vacuum voltage ensuring the use of the welding machine in environments with high electrical risk thus offering maximum safety to the operator

- Compliant with Industry 4.0 the new hardware structure implements a web server (through the Ethernet LAN port or, with an external kit, via Wi-Fi) that allows the operator to carry out all those activities that require the collection and processing of data, welding parameters configuration, diagnostics and remote assistance

- Remote control mode from personal computer, tablet or smartphone

- 2 USB ports for download and software update

- Equipped with digital ammeter/voltmeter with 1% accuracy and thermal protection devices

- Easily removable cooling grille

[Art. 396.55] Strong version on request with 50/60 Hz, (200) – 220 – 440 – 480 V, three-phase autotransformer

-

BINZEL 'ABITIG 450 W’ TIG torch

[Art. 1256] -

BINZEL 'ABITIG 450 W' UP/DOWN TIG torch

[Art. 1258] -

Remote control for regulating welding current

[Art. 187] -

5 m extension cable for remote control

[Art. 1192] -

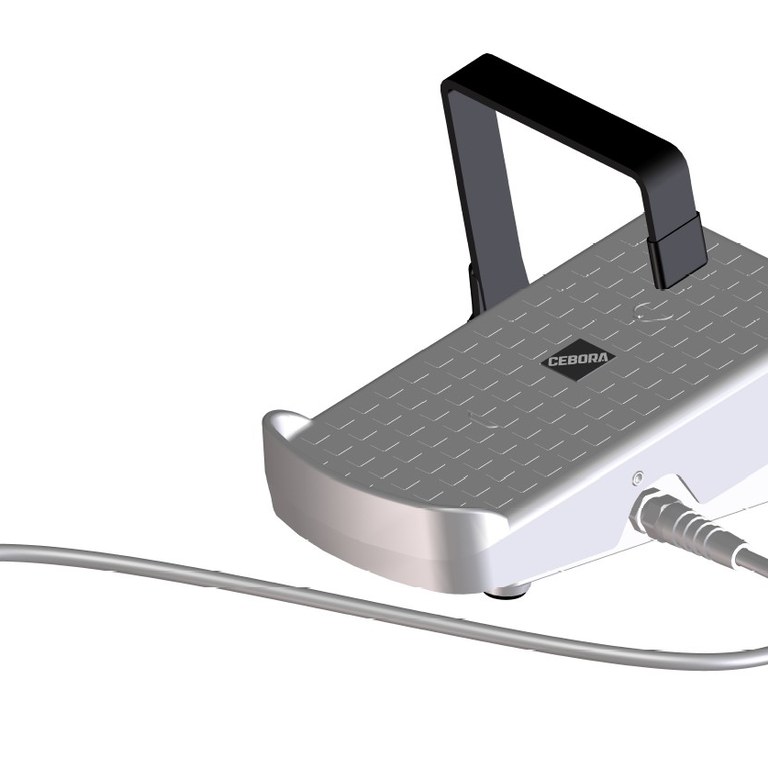

Wireless pedal control for welding current adjustment

[Art. 127] -

Wireless pedal control for welding current adjustment

[Art. 189] -

Connection linking torch and pedal control

[Art. 1180] -

Flowmeter with 2 pressure gauges

[Art. 1450] -

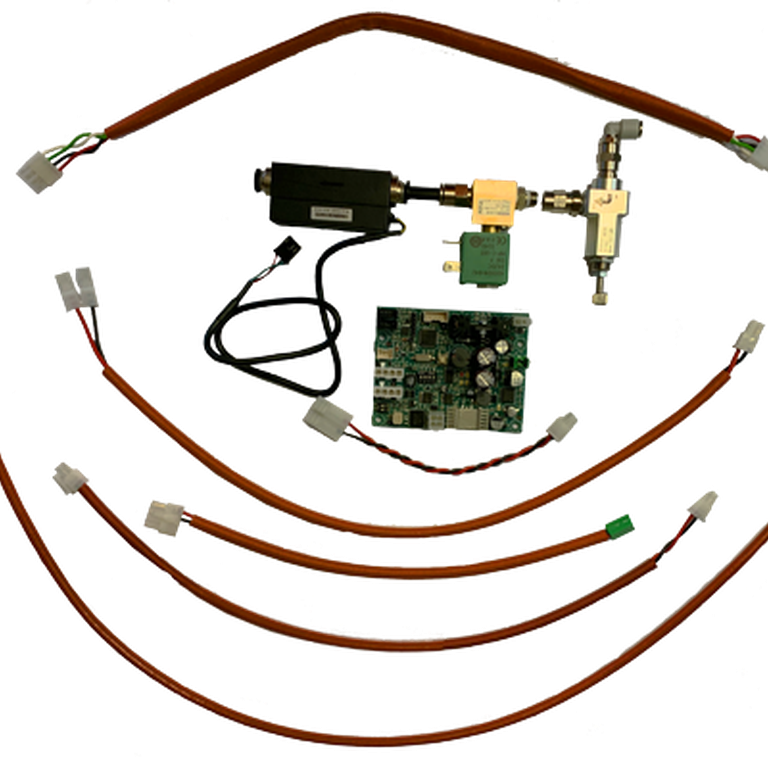

Kit gas flow regulator

[Art. 436.01] -

Remote control panel

[Art. 438] -

Connection between power source and control panel

[Art. 2065] -

Work return lead (3,5 m - 50 mm²)

[Art. 2073] -

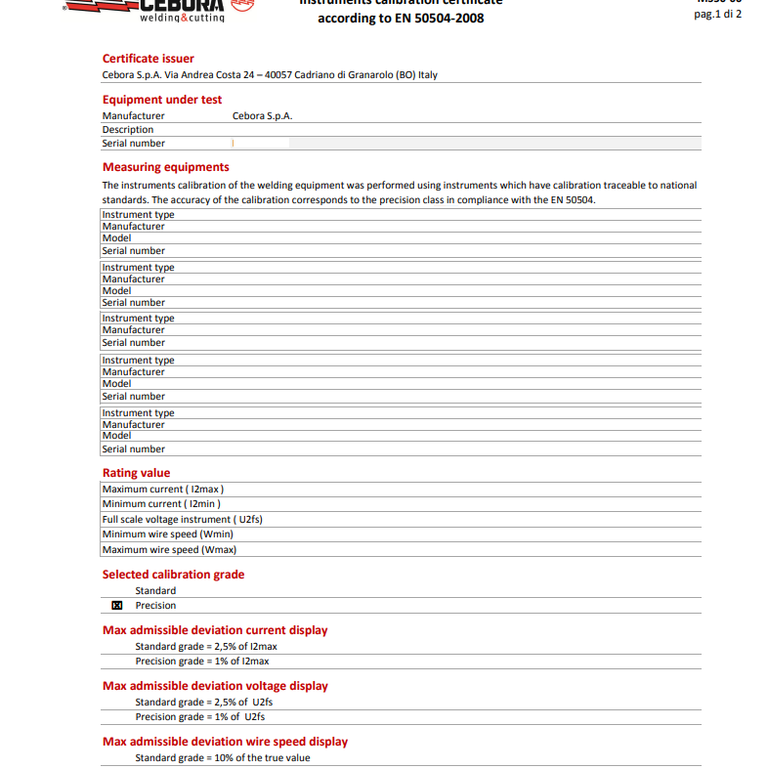

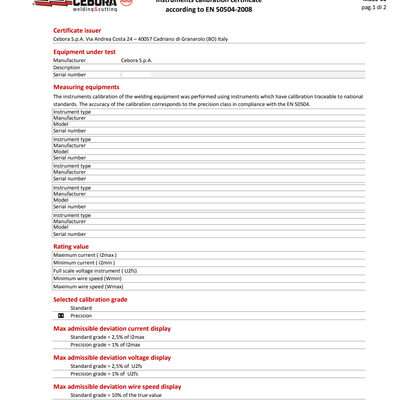

Calibration certificate

[Art. 803]

| Art. | 396 | Technical Specifications | ||

|---|---|---|---|---|

|

TIG |

MMA | |||

|

400 V 50/60 Hz |

Alimentazione trifase |

|||

|

20 A |

Fusibile ritardato |

|||

|

18,2 kVA 50% |

17,8 kVA 45% |

Potenza assorbita |

||

|

3 ÷ 450 A |

10 ÷ 360 A |

Campo di regolazione della corrente |

||

|

450 A 50% |

360 A 45% 340 A 60% 320 A 100% |

Fattore di servizio (10 min. 40° C) |

||

|

IP23S |

Grado di protezione |

|||

|

112 kg |

Peso |

|||

|

588x1120x1010 mm |

Dimensioni (LxPxH) |

|||

- Chemical industry

- Heavy metal fabrication

- Construction

- Building and road construction industry

- Handcrafting

- Food Industry

- Industrial & Energy plant

- Construction of agricultural,railway and heavy vehicles

- Routine maintenance

- Agricultural industry

- Off-shore industry