Sectors

WIN TIG AC-DC 180 M

INVERTER SINGLE PHASE COMPACT POWER SOURCE FOR MMA AND TIG AC-DC WELDING. HIGH FREQUENCY IGNITION

![]() 230 V 50/60 Hz +15%/-20%

230 V 50/60 Hz +15%/-20%

Benefits

User-friendly LCD Display

Equipped with XP, APC and DC TIG functions

AC e MIX AC+DC functions

AC Frequency is now adjustable from 50 to 200 Hz

Our power sources have got International Certifications and Approvals

![]()

Download

Parts and support

Count on our fast support, maintenance and parts supply services to ensure work continuity.

Extend your warranty!

Just bought a new Cebora welding power source? Register your product within 15 days to extend your warranty from 12 to 24 months.

Choose TIG Cebora

WIN TIG AC-DC 180M

WIN TIG AC-DC 180 M is an inverter single phase power source for TIG and MMA/SMAW welding except for AWS6010 coated electrodes

- User-friendly LCD Display

- EVO LIFTfunction allowsto place the electrode in the exact position avoiding the piece oxidation and the heat control

- EVO START function in order to optimize edge junction

- APC TIG (Active Power Control) welding process which guarantees a deeper penetration, a more stable arch, avoids the electrodes to get stuck to the piece, allows to adapt the arc to the welding conditions only with the torch movement

- AC+DC TIG welding process for aluminium welding and its alloys.

- Through the DC mode, more penetrated welds and enhanced welding speeds can be reached with consequent reduced deflection of the workpiece

- intermittence Pause Time Welding function which makes welding clearer with a time regulation in a second cents range

- Pulse functionto be adjusted up to 2,5 kHz

- eXtra Pulse (XP) function: avery high frequence pulse that works on small thicknesses where the transferred heat must be minimal

- Possibility to match a low pulse frequence to the XP process in order to improve the penetration and the welding speed on small-medium thicknesses.

- JOB function which makes it possible to save up to 9 welding programs

- Wiz function helping the operator to take quick decisions based on the desired welding process

- AC MMA welding process, suitable for welding electrodes on magnetized sheet metal, prevents the "magnetic blow" in the welding of iron boxes and it is usually employed in maintenance work

- The power source can also be powered by motor-driven generators of appropriate power (min. 8 kVA)

-

BINZEL 'ABITIG 200’ TIG torch

[Art. 1260] -

BINZEL 'ABITIG 200' UP/DOWN TIG torch

[Art. 1262] -

Power source transport trolley

[Art. 1653] -

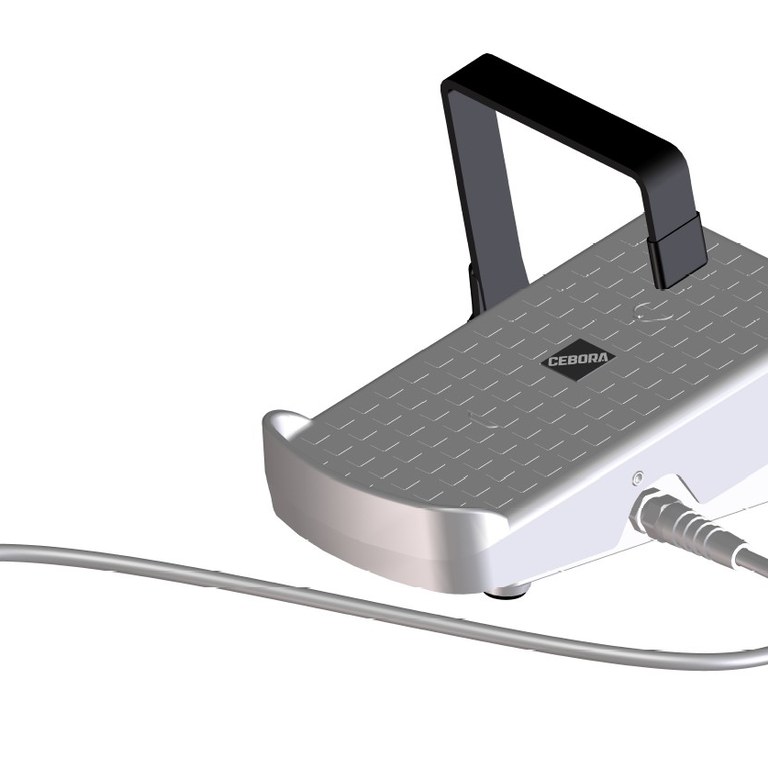

Remote control for regulating welding current

[Art. 187] -

5 m extension cable for remote control

[Art. 1192] -

Wireless pedal control for welding current adjustment

[Art. 127] -

Connection linking torch and pedal control

[Art. 1180] -

Flowmeter with 2 pressure gauges

[Art. 1450] -

Work return lead (3,5 m - 25 mm²)

[Art. 2072]

| Art. | 558 | Technical Specifications | ||

|---|---|---|---|---|

|

TIG |

MMA | |||

|

230 V 50/60 Hz |

Alimentazione monofase |

|||

|

16 A |

Fusibile ritardato |

|||

|

4,4 kVA 25% |

4,4 kVA 30% |

Potenza assorbita |

||

|

5 ÷ 180 A |

10 ÷ 130 A |

Campo di regolazione della corrente |

||

|

180 A 25% |

130 A 30% 100 A 60% 90 A 100% |

Fattore di servizio (10 min. 40° C) |

||

|

IP23S |

Grado di protezione |

|||

|

17,5 kg |

Peso |

|||

|

207x500x411 mm |

Dimensioni (LxPxH) |

|||

- Chemical industry

- Light metal fabrication

- Handcrafting

- Body shop

- Routine maintenance

- Agricultural industry