Sectors

PLASMA PROF 255 HQC

Mild Steel Stainless Steel Aluminium O2-Air H35-N2 N2 -H2O H35-N2 N2 - H2O 40 mm 30 mm 30 mm 25 mm 30 mmMULTIVOLTAGE THREE-PHASE POWER SOURCE FOR HIGH QUALITY CUTTING

![]() Quality piercing:

Quality piercing:

Benefits

Software updating in few seconds

Possibility to choose digital or analogic interface

Simple programming thanks to Sinergic Gas Console

Water Secondary Console for a high-perfomance Aluminum and Steel cut

Our power sources have got International Certifications and Approvals

![]()

Download

Parts and support

Count on our fast support, maintenance and parts supply services to ensure work continuity.

Extend your warranty!

Just bought a new Cebora welding power source? Register your product within 15 days to extend your warranty from 12 to 24 months.

Choose Plasma cutting Cebora

PLASMA PROF 255 HQC

Multi-voltage three-phase (220/230V-380/400V-415/440V 50/60Hz) power source with Chopper tecnology for High Quality Cutting with cooling unit included. PLASMA PROF 255 HQC is equipped with automatic system for plasma cutting with the following configurations: CNC or Robot configuration with Analogic or Digital interface

- Top-quality ARM microprocessor

- New and extremely reliable hardware e software

- Flexibility in the adjustment of the cutting current

- USB port for the software update

- CP 450G Torch consistent with all the HQC CEBORA power sources, both for 2D and 3D, up to 45 degree tilt angle

- PGC Synergic Manual Gas Console: designed to manage the cutting parameters in a user-friendly way

- APGC Automatic Gas Console: to control in real-time all the gas flows and the automatic switch between cutting and marking

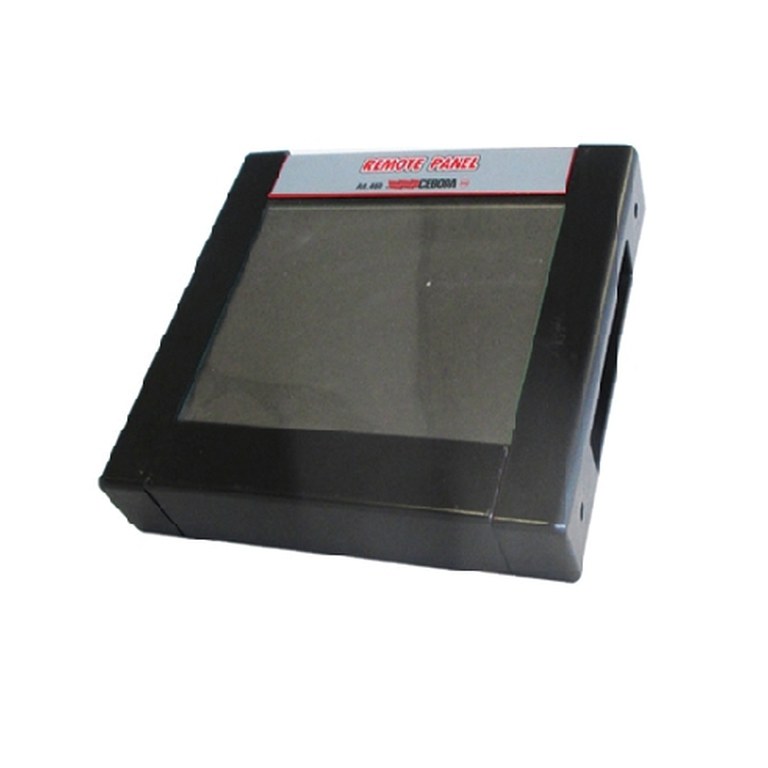

- HQC CONTROL PANEL, a digital touchscreen remote control panel (suitable for automatic partially integrated systems )

- Water Secondary Console, for stainless steel and aluminium cutting using water like a secondary fluid. Designed for Manual and Automatic Gas Console

- HF and Gas valves Unit that integrates the two components in a single one, just using CP 540G Cebora torch for any CNC machine size

--

- Art. 949.00 Power source version with Analogic Digital interface

- Art. 949.40 Power source version with CANopen Digital interface

- Art. 949.41 Power source version with PROFIBUS Digital interface

- Art. 949.42 Power source version with DeviceNet Digital interface

- Art. 949.43 Power source version with EtherCAT Digital interface

- Art. 949.44 Power source version with EtherNet/IP Digital interface

Special consumables for Mild Steel:

- 50 A Speed, to increase the cutting speed while keeping top performance

- 120 A EXP (EXtreme Piercing) for pierce heavy duty without overdimensioning the HQC system

- 250 A QPC (Quality Production Cutting) to get the best compromise between quality and productivity

| Art. | 949 | Technical Specifications |  |

|---|---|---|---|

|

220/230 V |

Alimentazione trifase |

||

|

175 A |

Fusibile ritardato |

||

|

46 kW |

Potenza di installazione max |

|

|

51 kVA 100% |

Potenza assorbita |

||

|

5 A ÷ 250 A |

Campo di regolazione della corrente |

||

|

250 A 100% |

Fattore di servizio (10 min. 40° C) |

||

|

ELECTRONIC |

Regolazione continua Stepless regulation |

||

|

IP21S |

Grado di protezione |

||

|

406 kg |

Peso |

||

|

685x995x1255 mm |

Dimensioni (LxPxH) |

||

-

CEBORA CP 450 G DAR SHIELDED Robot Torch

[Art. 1223.02] -

CEBORA CP 450 G SHIELDED torch for CNC (294 mm)

[Art. 1224] -

CEBORA CP 450 G SHIELDED torch for CNC (386 mm)

[Art. 1225] -

APGC - Automatic gas console

[Art. 466.01] -

HV 19/1 ignition unit

[Art. 464] -

PGC-D manual gas console

[Art. 480] -

PGC-H2 manual gas console

[Art. 487] -

Gas valve unit

[Art. 469] -

HF unit + gas valves (Robot)

[Art. 462] -

HF unit + gas valves (CNC)

[Art. 459] -

WSC - Water Secondary Console

[Art. 485] -

Remote panel for automatic gas console

[Art. 460.01] -

Coolant

[Art. 1514] -

Connection between power source and gas console

[Art. 1189] -

Gas connection between console and gas valve unit

[Art. 1166] -

Connection between power source and ignition unit

[Art. 1169] -

Connection between power source and panel

[Art. 1199] -

Work return lead (12 m - 70 mm²)

[Art. 1289.10] -

Extended analog interface kit

[Art. 425]

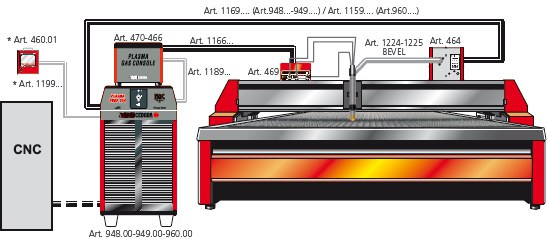

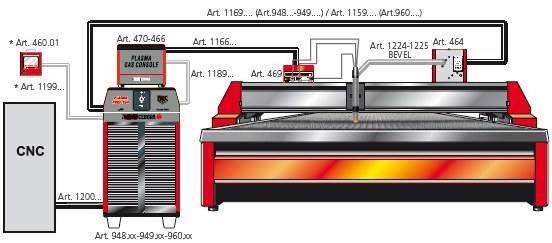

CNC SYSTEM LAYOUT

- [Art. 1224 - 1225] CEBORA CP450 ROBOT torch. Shielded with short (294 mm) or long (386 mm) handle

- [Art. 470] Manual gas Console [Art. 466] Automatic gas Console

- [Art. 469] Gas valve units + [Art. 464] HV19/1 ignition unit or [Art. 459] Ignition unit / plasma valves unit

- [Art. 1166] Gas connection between console[Art. 470/ 466] and gas valve units

- [Art. 1169] Gas connection between power source and ignition unit

- [Art. 1189] Extension lead between power source and console

- [Art 460.01] An option to use only with Automatic Gas Console [Art. 466]

CNC SYSTEM LAYOUT WITH ANALOGIC INTERFACE

CNC SYSTEM LAYOUT WITH DIGITAL INTERFACE

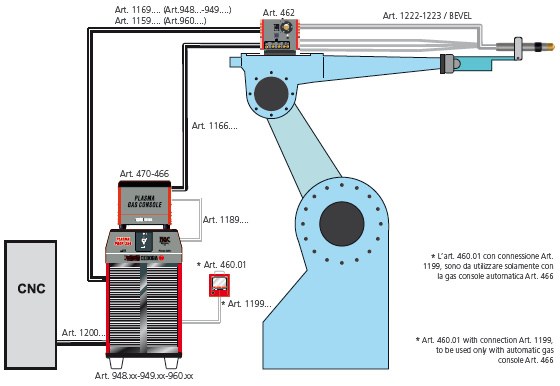

ROBOT SYSTEM LAYOUT

- [Art. 1223.02] CEBORA CP450 ROBOT torch. Shielded with short handle (294 mm)

- [Art. 470] Manual gas Console [Art. 466] Automatic gas Console

- [Art. 462] HF unit + gas valvole unit

- [Art. 1166] Gas connection between console[Art. 470/ 466] and gas valve units

- [Art. 1169] Gas connection between power source and ignition unit

- [Art. 1189] Extension lead between power source and console