Sectors

SYNSTAR 270 T SRS edition

MULTIPROCESS INVERTER THREE-PHASE COMPACT POWER SOURCE FOR MIG/MAG, DC TIG and MMA WELDING

![]() 400 V 50/60 Hz +15% / -20%

400 V 50/60 Hz +15% / -20%

Benefits

User-friendly LCD touchscreen Display

Pulse and Double Pulse functions

4-roller wire feed unit and over 30 synergic curves

Possibility of using 2003 Cebora Push-Pull torch

Software updating in few seconds

Pre-arranged for cooling unit

Our power sources have got International Certifications and Approvals

![]()

Download

Parts and support

Count on our fast support, maintenance and parts supply services to ensure work continuity.

Extend your warranty!

Just bought a new Cebora welding power source? Register your product within 15 days to extend your warranty from 12 to 24 months.

Choose MIG/MAG Cebora

SYNSTAR 270 T SRS edition

SYNSTAR 270 T is a multiprocess inverter three-phase power source for MIG/MAG, DC TIG ( with 'Cebora Lift' ignition) and MMA welding with special SRS function included

- Cebora aluminium 4-roller-wire feed unit ( Ø 30 mm )

- Equipped with transportation trolley, ground lead ( 3 m - 35 mm2 )and clamp

- Pre-arranged for cooling unit

- Over 30 synergic curves for Solid wire ( Ø 0,6/0,8/0,9/1,0/1,2 mm)

- Supplied with double level of current (MIG Short process), Pulse and double Pulse

- Equipped with SRS standard welding process (Spatter Reduction System) in order to completely achieve spatters free welds and with reduced heat input

- System calibration procedure which allows complete adjustment of all welding parameters and process variables (from the features of the welding torch, to the extension lead used between the transporting trolley and the power source);

- TIG Pulse upgrade [Art. 234]

- Equipped with dust filter to protect the power source against iron powders

- The power source is supplied with many adjustable functions which can be accessed from the LCD touchscreen Display, including:

- Arc Length, 2/4 strokes, Spot Time, Pause Time, Inductance, Burn Back, Soft Start, Post-Pre gas, etc.

- SHORT or PULSE process

- Three importants specific functions dedicated to an optimal aluminum welding (3 levels, Automatic Hot Start, Automatic Crater Filler) - Equipped with digital ammeter / voltmeter with 1% accuracy and thermal protection devices

- USB port for software update

- Second gas connection and additional dedicated solenoid valve when using the power source in TIG mode

- MIG/MAG torch with "Euro" adapter + TIG torch adapter

- It is possible to work with two different types of coils: Ø 200 mm or Ø 300 mm

-

CEBORA PUSH-PULL (UP/DOWN) torch

[Art. 2003] -

'CEBORA 280 A’ MIG torch - air cooled

[Art. 1242] -

'CEBORA 380A’ torch - Water-cooled

[Art. 1241] -

BINZEL 'ABITIG 450 W’ TIG torch

[Art. 1256] -

Aluminium kit

[Art. 1933] -

4.3 m sheath assembly for aluminium wire

[Art. 1930] -

GRV14 torch cooling unit

[Art. 1681] -

Flowmeter with 2 pressure gauges

[Art. 1450] -

Electrode holder and work return lead

[Art. 1284.05] -

Connection between power source and TIG torch

[Art. 2068] -

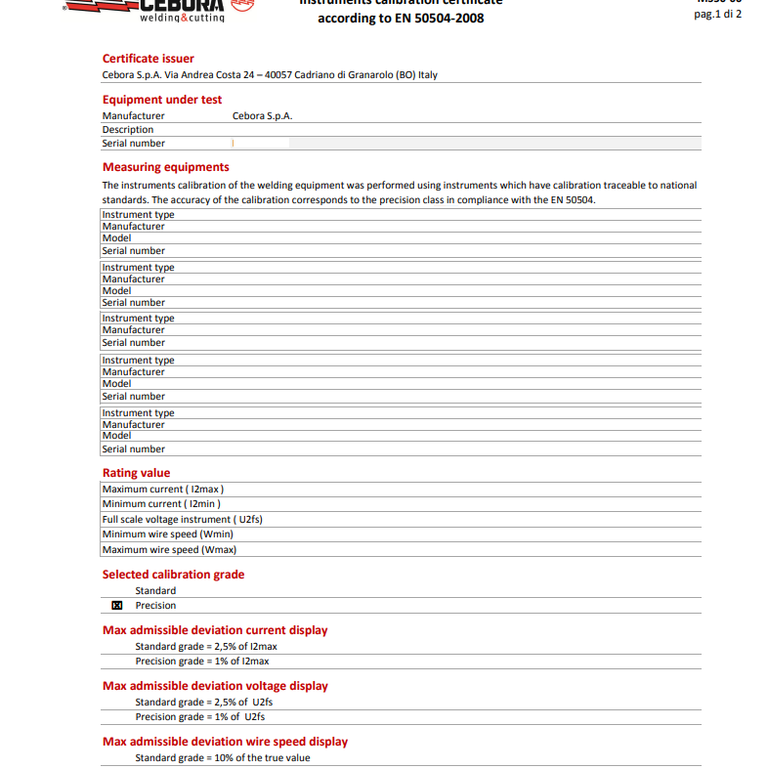

Calibration certificate

[Art. 803]

| Art. | 564 |  |

||

|---|---|---|---|---|

|

MIG - TIG |

MMA |

|

||

|

400 V 50/60 Hz |

|

Alimentazione trifase |

||

|

16 A |

|

Fusibile ritardato |

||

|

9,3 kVA 20% |

9,5 kVA 20% |

Potenza assorbita |

||

|

10 ÷ 270 A |

10 ÷ 250 A |

Corrente min.-max. ottenibile in saldatura |

||

|

270 A 20% |

250 A 20% |

Fattore di servizio (10 min. 40° C) |

||

|

Electronic |

|

Regolazione continua |

||

|

0,6/0,8/0,9/1,0/1,2 Fe |

|

Curve sinergiche in dotazione standard |

||

|

Ø 300 mm/15 kg |

|

Bobina filo trainabile max. |

||

|

IP23S |

|

Grado di protezione |

||

|

68 kg |

|

Peso |

||

|

510x1020x865 mm |

|

Dimensioni (LxPxH) |

||

- Chemical Industry

- Heavy metal fabrication

- Construction

- Building and road construction industry

- Handcrafting

- Food industry

- Body shop

- Industrial & Energy plant

- Construction of agricultural, railway and heavy vehicles

- Routine maintenance

- Equipment for means of emergency

- Construction of tanks

- Off-shore industry

- Mines