Разделы

SYNSTAR 350 TS

INVERTER THREE-PHASE DUAL-VOLTAGE POWER SOURCE FOR MIG/MAG AND MMA WELDING

![]() 230-400 V +15%/-20% 50/60 Hz

230-400 V +15%/-20% 50/60 Hz

Преимущества

User-friendly LCD touchscreen Display

Pre-arranged for Pulse and Double Pulse functions

4-roller wire feed unit

Dual-voltage power source

Our power sources have got International Certifications and Approvals

![]()

Download

Запасные части и техпомощь

Доверьтесь нашему оперативному сервису по предоставлению техобслуживания, ремонта и поставке запасных частей, чтобы обеспечить непрерывность своих рабочих процессов.

Продлите гарантию!

Вы только что купили новый сварочный генератор Cebora? Продлите гарантию на срок от 12 до 24 месяцев, зарегистрировав свое изделие в течение 15 дней.

выберите MIG/MAG Cebora

SYNSTAR 350 TS

Новый SYNSTAR 350 TS представляет собой трехфазный инверторный генератор для сварки MIG/MAG и MMA

- Dual-voltage power source

- Aluminium 4-roller wire feed unit (Ø 30 mm)

- Pre-arrenged cooling unit

- Equipped with power source transportation trolley, ground lead (3,5 m - 50 mm2) and clamp

-

The yield of this power source is the highest among the comparable ones and allows to obtain a maximum current of 350 A 60% of the duty cycle (10 min. 40°C),

according to IEC 60974-1 standards - The power source has many adjustable functions which can be accessed from 5 ” colour Display Touch-screen, including:

- Arc Length, 2/4 strokes, Spot Time, Pause Time, Inductance, Burn Back, Soft Start, post-pre gas, etc.

- SHORT or PULSE function

- Three importants specific functions dedicated to an optimal aluminum welding (3 levels, Automatic Hot Start, Automatic Crater Filler) - Welding programs for wires ø 0,8/1,0/1,2 mm., and also for pulsed synergic programs as well as of stainless steel and aluminium programs

- MIG SHORT HD (High Deposit)

- Upgrade MIG Pulse and HD Pulse [Art. 238]

- Upgrade MIG double current level function [Art. 813]

- Upgrade MIG Double Pulse [Art. 238 + 813]

- Electrodes that can be used Ø 1,6 ÷ 6,0 mm

- Firmware update through USB port and RS232

- Prearranged for integration into simple automation via optional analog interface kit (Art. 456)

| Art. | 379 | Technical Specifications | ||||

|---|---|---|---|---|---|---|

|

MIG/MAG |

|

MMA |

|

|

||

|

230 V +15% / -20% |

400 V +15% / -20% |

230 V +15% / -20% |

400 V +15% / -20% |

Alimentazione trifase |

||

|

28 A |

16 A |

28 A |

16 A |

Fusibile ritardato |

||

|

13,3 kVA 40% |

|

13,6 kVA 40% |

|

Potenza assorbita |

||

|

10 ÷ 340 A |

10 ÷ 350 A |

10 ÷ 320 A

|

10 ÷ 330 A |

Corrente min.-max. ottenibile in saldatura |

||

|

340 A 40% |

|

320 A 40% |

330 A 60% |

Fattore di servizio (10 min. 40° C) |

||

|

Electronic |

|

Regolazione continua |

||||

|

0,8/1,0/1,2 Fe |

|

Filo utilizzabile |

|||

|

Ø 300 mm/18 kg |

|

Bobina filo trainabile max. |

||||

|

IP23S |

|

Grado di protezione |

||||

|

95 kg |

|

Peso |

||||

|

527x1078x1398 mm |

|

Dimensioni (LxPxH) |

||||

-

Горелка CEBORA 380A

[Art. 1239] -

Горелка CEBORA 380A - С водным охлаждением

[Art. 1241] -

Горелка CEBORA 500A (UP / DOWN) - с водяным охлаждением

[Art. 1245] -

Комплект цифро-аналогового адаптера для разъема горелки UP/DOWN

[Art. 2053] -

GVR22 блок охлаждения горелки

[Art. 1686] -

Комплект интерфейса для горелок PUSH-PULL

[Art. 447] -

Соединение между генератором и тележкой

[Art. 2069] -

Расходомер с 2 манометрами

[Art. 1450] -

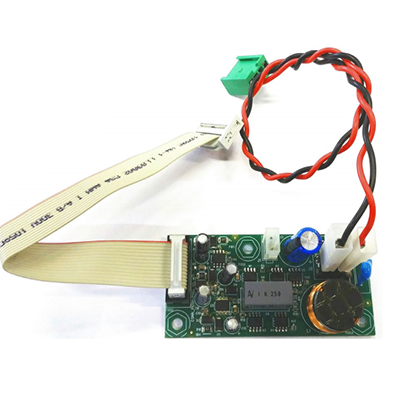

Комплект для алюминиевой проволоки

[Art. 1933] -

Оплетка 3,5 м для алюминиевой проволоки

[Art. 1930] -

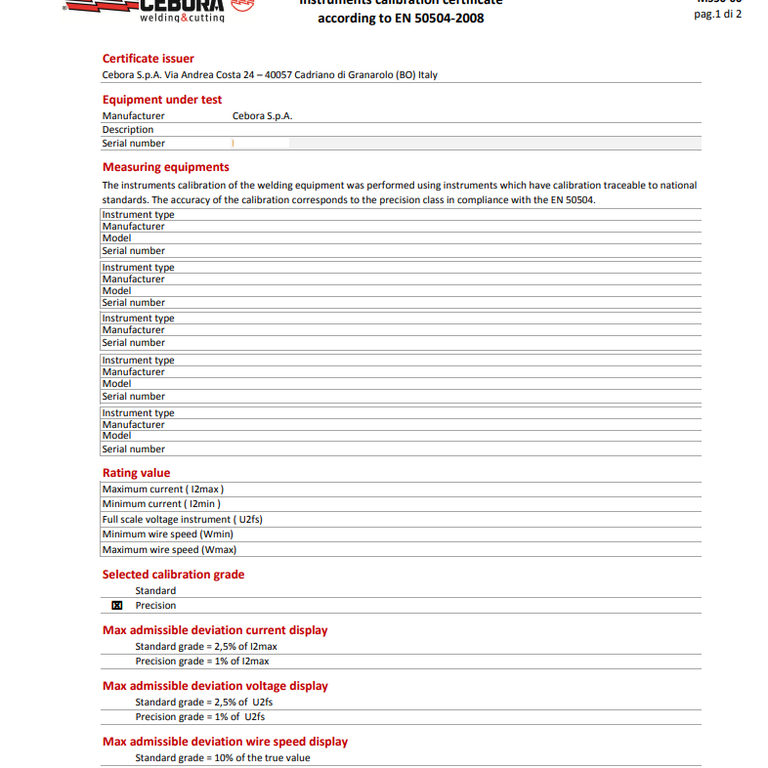

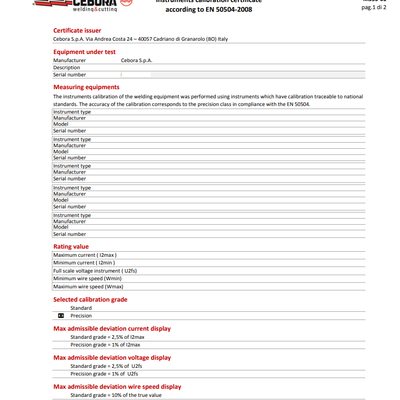

Калибровочный сертификат

[Art. 803]

- Chemical industry

- Heavy metal fabrication

- Heavy-medium metal fabrication

- Construction

- Building and road construction industry

- Handcrafting

- Food industry

- Industrial & Energy plant

- Construction of agricultural, railway and heavy vehicles

- Routine maintenance

- Construction of tanks

- Off-shore industry